Single and multiple titanium bases on straight and angled conical abutments and including blanks

TITANIUM BASES

Titanium bases are available as direct implants and on straight or angled conical abutments.

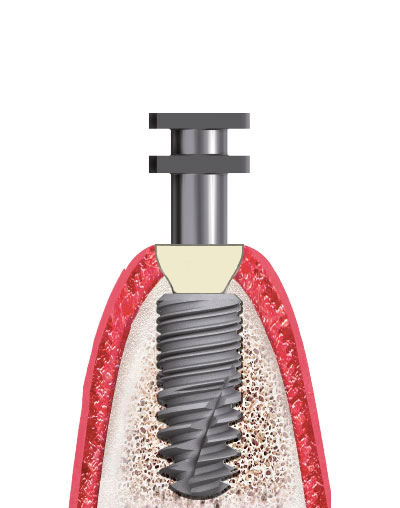

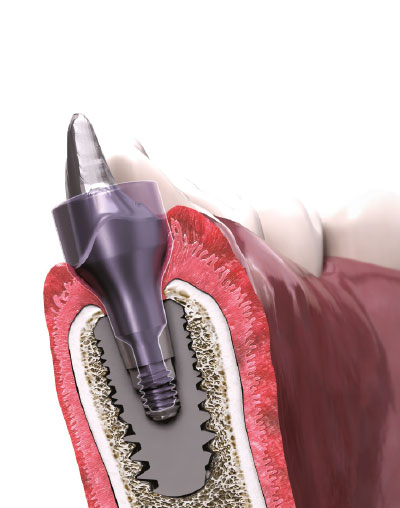

Titanium bases are designed to allow the manufacture of customised zirconia implant abutments, bars and bridges, providing optimum mechanical strength: the combination of a titanium base with the zirconia superstructure is particularly indicated as it absorbs the mechanical stresses transmitted by the zirconia structure.

These bases can also be used by the laboratory to make prostheses using conventional or digital techniques and then subsequently bonded onto the base.

Single bases can be adjusted by 1 to 2 mm in height, particularly in CAD software design (able to obtain a coronal height of 3 mm on the screen). Titanium bases are available in two diameters: 3.8 and 5.5 mm. The 3.8 mm diameter is restricted to the aesthetic sector: from to 5 to the 5. The 5.5 mm diameter is to be preferred in the posterior sectors.

Multiple bases are available for straight and angled conical abutments.

All our titanium bases are available in the CAD software libraries.